TUBE BENDERS

CNC Tube Benders

NC Tube Benders

Special Purpose Benders

The SOCO SB-Oil Tube Master is a dedicated CNC Brake Line Tube Benders. Designed for small tubing OD8 mm x 0.7t, especially Bundy Tubes and Hydraulic Lines. With multiple electric axis and a unique design to allow bending the most complex shapes and parts. It offers the most advanced solution ( Pipe Bending,Tube Bending ) and performance in its range.

Suitable for Brake Line tubing up to 4000mm ( Optional 5000mm ) and unparalleled Pipe Bending Speed. This CNC Pipe Bending Machines with optional Automatic Loading and Unloading Interface.

- 3 Electric Axis controlling tube bending, tube rotation and carriage movement

- Automatic bending head reversal (left-to-right) when reaching central clamping area, providing a fully automatic cycle for the entire bending process

- Optional Automatic Loading and Unloading Interface

Performance

- Centralized clamping and rotation system for true simultaneous moving of all axis

- Lowest cycle times because minimal number of moving parts

- Suitable for brake line tubing up to 4000mm ( Optional 5000mm )

- Unparalleled Pipe Bending Speed —– ” 39.2 seconds, 14 Bends ” ]

Maximum Working Area = Minimal Interference:

- No interference with machine bed

- No conventional bending arm

- No pressure die and wiper die seat interferences

- Central clamping and rotation away from bending zone

- Overmode (Arm Return Mode) capabilities

Software

- May program up to 50 bends per part, with on-screen 3D part display

- Data entry for both XYZ and YBC coordinates

- Overmode (Arm Return Mode) offers flexibility to offset each bend and avoid bending interferences.

- Integrated Automatic Bending Compensation and Reverse Engineering of bends when connected to CMM Measuring systems

- Connection to Local Area Network ( LAN ) ( Optional )

All Electric Pipe Bending Machines

Left and Right Tube Bending Machine with 5 ~ 10 Electric axis

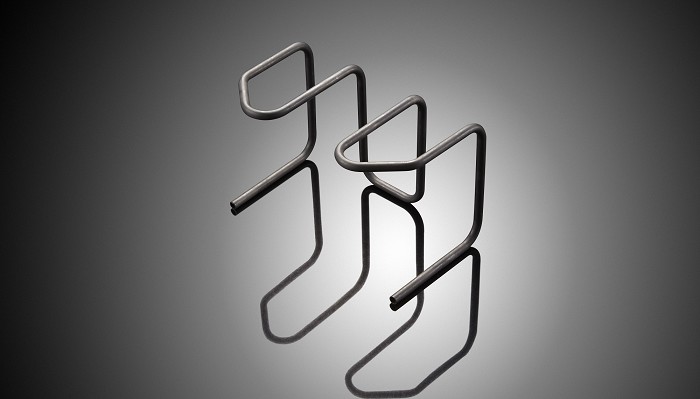

The new SOCO CNC Tube Bender which is equipped with Left and Right Bending Technology for maximum flexibility and minimal interference. The “ U type” pipe bender is especially suitable for complex parts and shapes, such as automotive head rest, fuel lines, heating and cooling systems. This pipe bender is equipped with 5 ~ 10 electric CNC axes, 2 ~ 3 bending stacks and uses SOCO’s unique DGT technology ( Direct Gear Transmission ).

- Left and Right Tube Bending capabilities in the same cycle

- DGT technology – Gear Transmission Bending for Highest Speed and Accuracy

- Easy Programming – Setup a part in the same way as a single directional bend

- Elongated bending neck for maximum working area

- 5 ~ 10 Electric servo controlled axes pipe bending machine

- 2 speeds + Early mandrel extraction

- Automatic Groove Detection System for ensure the tube in right direction before bending (Optional)

- Automatic mandrel lubrication

- Touch Screen with IPC ( Industrial PC )

- Multi-stacks + Multi-Radius

- Independent pressure die system for each bending stack

- Optional Automatic Loaders (AF), Groove and Seam Detectors and Automatic Unloaders (AUL)

Advanced DGT

SOCO’s unique DGT technology ( Direct Gear Transmission ) is the worldwide patented bending system that brings you the most efficient and stable bending process, offering the highest accuracy and repeatability in draw and roll bending. Most SOCO CNC tube bender equipped with this technology.U series Pipe Bender equipped with SOCO DGT technology.The Advantages of DGT :

- Chain free transmission

- Built-in gearbox with direct connection to electric servo

- Highest transmission performance ( 90%+ efficiency ) against other gear based systems

- High tube bending accuracy ( +- 0.05° ~ +-0.1° )

- Low noise level

- Maximum Working Area = Minimal Interference

- Elongated neck for superior clearance (***)

- Compact bending head

- Side carriage and bending head (***)